With the rapid development of society, in order to meet the needs of customers for drilling in different formations and improve drilling efficiency. Then, pneumatic water well drilling rigs are developing in the direction of multi-purpose drilling rigs, full hydraulic transmission, and operations. That is, the drilling rig is equipped with various equipment and accessories, as well as various drilling methods such as percussion, hydraulic, hydraulic transmission, and hydraulic drive. Pneumatic water well drilling rigs can use rotary and down-the-hole hammers; mud flushing, compressed air flushing, and forward and reverse circulation flushing can also be used.

What Is Pneumatic Water Well Drilling Rigs?

A pneumatic water well drilling machine is a water well drilling machine powered by compressed air pressure. It is a highly efficient water well-digging machine that can drill holes or break hard surfaces to drill wells. For example, low water tables, large amounts of silt, clay, exposed bedrock, or large rocks, etc.

The pneumatic water well drilling rig Machine is also commonly known as pneumatic drills or air drills. The pneumatic drill is one of the most efficient drilling tools on the market in terms of capacity, productivity, and features. For example, a sledgehammer can hit the ground ten times a minute, while a pneumatic drill can hit the ground more than 1,000 times a minute. This level of efficiency makes the pneumatic water well drilling machine the first choice for drilling holes in hard surfaces or drilling deeper wells.

Technical Specification Of Pneumatic Water Well Drilling Rigs

| Model | YK-180 | YK-200 | YK-260 | YK-300 | YK-350 |

| Drilling Depth | 180m | 200m | 260m | 300m | 350m |

| Drilling Diameter | 90-315mm | 90-315mm | 90-315mm | 90-315mm | 90-315mm |

| Working Wind Pressure | 1.7-3.0Mpa | 1.7-3.0Mpa | 1.7-3.0Mpa | 1.7-3.0Mpa | 1.7-3.3Mpa |

| Air Consumption | 17-35m³/min | 17-35m³/min | 17-35m³/min | 17-35m³/min | 17-35m³/min |

| Drill Pipe Length | 3m | 3m | 3m | 3m/6m | 3m/6m |

| Drill Pipe Diameter | 76/89mm | 76/89mm | 76/89mm | 76/89mm | 76/89/102mm |

| Axial Pressure | 4T | 5T | 7T | 8T | 10T |

| Lifting Force | 14T | 15T | 16T | 17T | 25T |

| Maximum Swing Torque | 4500-6500Nm | 4900-6900Nm | 5400-7400Nm | 7200-8500Nm | 8800-9500Nm |

| Rotational Speed | 50-70r/min | 50-70r/min | 50-70r/min | 50-115r/min | 50-115r/min |

| One-time Advance Length | 3000mm | 3000mm | 3000mm | 6000mm | 6000mm |

| Crawler Speed | 2.5km/h | 2.5km/h | 2.5km/h | 2.5km/h | 2.5km/h |

| Crawler Gradeability | 35° | 35° | 35° | 35° | 35° |

| Total Weight | 4T | 4.5T | 5T | 7.5T | 9T |

| Dimensions | 3.9*1.7*2.2m | 3.9*1.7*2.2m | 4*1.7*2.2m | 4.3*1.8*2.7m | 4.5*1.9*2.7m |

| Engine | 58KW | 65KW | 76KW | 85KW | 92KW |

What Is The Scope Of Application Of Pneumatic Water Well Drills?

Pneumatic water well drills are mainly suitable for industrial well drilling, civil well drilling, detection wells, precipitation wells, rescue wells, ground source air-conditioning holes, coal bed methane, natural gas, oil extraction, and other projects, and geothermal well drilling. They have the advantages of compact structure, fast footage, flexible movement, and a wide range of applications. It is especially suitable for taking water in mountainous and rocky formations.

What Are The Unique Characteristic Of The Pneumatic Water Well Drilling Rigs?

- Engine: Equipped with a high-quality turbocharged engine with strong power.

- Patented technology: patented composite boom, double oil cylinder lift.

- Unique design: Each drilling rig is equipped with a baffle on the main arm to protect the oil cylinder.

- Drilling rig chassis: Professional excavator chassis, sturdy and durable, heavy load, wide chain plate, the drilling rig uses rubber crawlers, high flexibility, and little damage to hard road surfaces.

- Good maintenance: Parallel transmission design, independent oil pump, sufficient power, reasonable distribution, unique hydraulic system design, simple maintenance, and low cost.

- Dual systems can be added: An aerodynamic system with the air compressor. Mud pump system with mud pump.

- Easy to operate: the operating system is simple and easy to operate, and it is convenient to load and unload on the truck.

What Are The Precautions For Using The Pneumatic Water Well Drilling Machine?

Understand Basic Operations

A pneumatic water well drilling machine is heavy drilling equipment. It requires great strength and safety precautions in its use. When the drill bit hits the ground, it creates severe vibrations that pose a risk to the operator. Therefore, before using it, the operator needs a detailed and detailed operation method of the machine. If conditions permit, professional training can be carried out, or technical support can be requested from relevant technical personnel.

Check Pneumatic Water Well Drilling Machine

- Check whether the machine equipment is complete and make sure that the parts are intact and there is no omission. Pay attention to checking whether the gas-water pipeline, the bolts of each part, and the connection of the nut joint are firm and reliable.

- Do not allow reverse rotation during drilling to prevent the drill pipe from falling into the hole. When the machine stops working in a short period of time, a small amount of compressed air should be given to prevent the sediment from intruding into the impactor.

- When working, pay attention to the sound of the impactor and the operation of the reduction box. If any abnormal phenomenon is found, stop the machine immediately for inspection.

- When adding a new drill pipe, special attention should be paid to the cleaning of the hole, so as to avoid sand and soil from mixing into the impactor, damaging the machine parts, or causing drilling stoppage accidents.

Maintenance Of Pneumatic Water Well Drilling Rig

- At the end of each work shift, the dirt on the surface of the machine must be cleaned.

- It is strictly forbidden to dismantle and disassemble the work surface (except for the case where it is disassembled into components for easy handling), so as to avoid losing parts and damaging key parts of parts.

- The drill pipe joints are lubricated with butter. The reducer is lubricated with butter.

【Whatsapp/Wechat/Phone】+8618337123872

Email: admin@ygdrillequipment.com

Good Quality Pneumatic Drills Rig For Drilling Wells

Precautions For Use Of Wind Motor

- Lubrication must be ensured before operation.

- The connection between the wind motor and the rubber hose must be firm.

- Before connecting the air motor and the rubber hose, the rubber hose should be carefully cleaned. You can open the pipeline for a few seconds, and then use compressed air to blow off the rubber hose before connecting.

- When it is found that the wind motor is not operating normally, it should stop working and carry out maintenance, and it is strictly forbidden to dismantle the working surface.

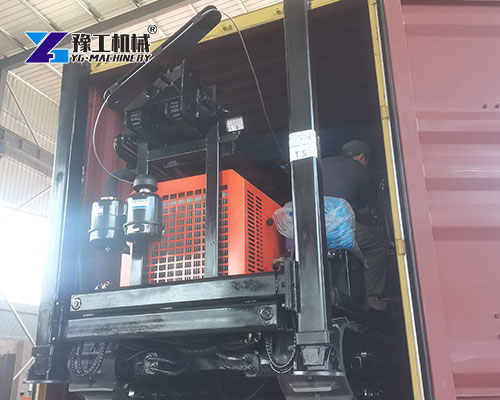

YG Machinery Pneumatic Water Well Drilling Rig Being Sold In Great Number

YG Machinery pneumatic water well drilling equipment can be widely used in various difficult environments. Drilling depth can reach 350 meters. Besides, we have various types of water well drilling rigs machine to choose from, including Small Water Well Drilling Rigs, Portable Well Drilling Machine, Truck Water Well Drilling Rig Machine, Trailer Mounted Water Well Drilling Rigs, Four-Wheel Tractor Mounted Borewell Drilling Rig Machine, Water And Gas Dual Water Well Drilling Rig, Wheeled Pneumatic Water Well Drilling Rig, etc. If you need a water well drilling rig with the best quality and efficiency, then YG Machinery’s Pneumatic Water Well Drilling Machine can meet all your needs.